The Benefits of Electroplating in Chennai

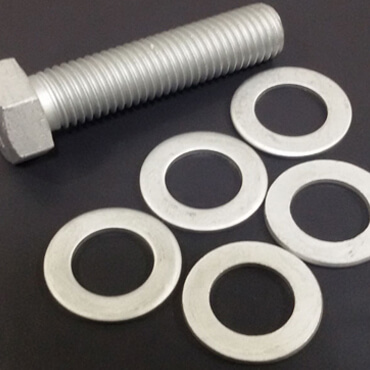

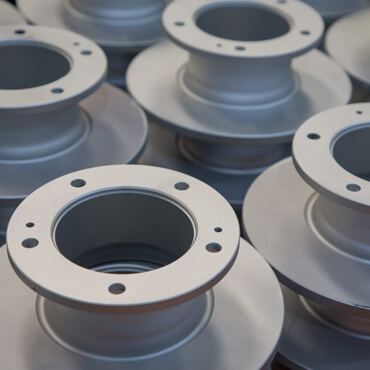

Electroplating is a process used to coat a conductive part with a thin layer of metallic material in order to provide different chemical, physical, and mechanical characteristics to a part that it would otherwise be unable to exhibit. An example of some properties that can be bestowed upon a part through metal plating would be such things as abrasion and wear resistance, lubricity, corrosion protection, and aesthetic qualities.

The Importance of Electroplating in Chennai

Electroplating works when submerging one or more pieces of metal into a solution that has ions of another metal-type dissolving in it. An electric current runs through both the plating project and the plating solution. The resulting electric charge causes ions of the plating solution to adhere to the open surface areas of the metal piece.

Chennai Top Electroplating Services

Electroplating is conducted in an electrolytic cell. The metal to be electroplated is connected to the cathode. The electrolyte consists of the salt solution of metal with which electroplating has to be done. The electrolyte ionizes to give positively charged ions (metal ions) which move towards the anode for electroplating the desired object.

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

ngcoater_login

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

ngcoater_login2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

ngcoater_login

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

ngcoater_login2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai