The Surprising Benefits of Dip Spin Coating in Chennai

The dip-spin coating process consists of cleaning, application, and curing. The parts are first cleaned and then pretreated to remove oxides. Once the pretreatment dries, we place them in the wire mesh basket and then submerge in the coating solution.

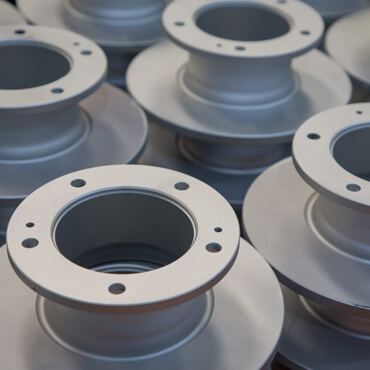

Dip Spin is method of applying a thin coating on small parts using centrifugal force to control film thicknesses. The force generated by the high rate of basket speed allows for consistent, even coating in a short period of time. As the spinning process ends the basket begins to slow and is removed from the rotating chamber while still in motion. This allows for the paint or coating to safely drain from the parts and basket.

Zinc flake coatings are applied using state-of-the-art dip-spin, dip coating or fully automated wet coating processes. As license holder of the leading suppliers, It’s a NG Coaters can offer these processes at its global facilities.

The Advantages of Using Dip-Spin Coating

Dip spin coating systems serve for the coating of mass goods in an efficient way, which are dipped in liquid coating materials either in baskets or racks depending on the range of parts.

Dip-spin coating has a number of benefits for your products:

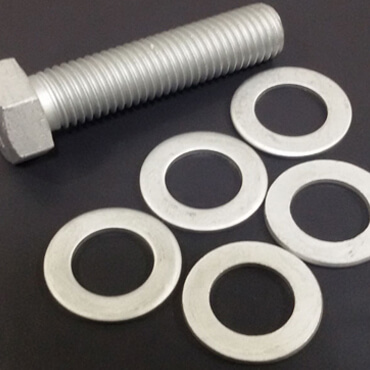

- Economical method for bulk processing small parts such as fasteners, nuts, bolts, stampings, and springs.

- Repeatable when even coverage is required, like for threaded parts.

- Well-suited for high-production coating.

- Transfer efficiency is high, normally 98% or more.

- We can efficiently combine multiple combinations of coatings.

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

ngcoater_login

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

ngcoater_login2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai

https://www.ngcoaters.in/wp-content/uploads/2022/08/Non-Electrolytically-Applied-Zinc-Flake-Coating.jpg

370

370

ngcoater_login

https://www.ngcoaters.in/wp-content/uploads/2022/08/NG-logo.png

ngcoater_login2022-09-23 10:57:172022-10-13 06:52:16Electroplating in Chennai